With the change in global trends, diversity and digital empowerment of consumers market demands are becoming increasingly unpredictable. More and more consumers have started looking at tailor made product and services making distribution much more complex.

To remain competitive, companies across industries must embrace this growing complexity while maintaining the benefits of simple, streamlined supply chains to deliver their aspirations of growth, cost, working capital and sustainability. Companies with diverse portfolio needs to look at something more promising instead of having one supply chain attempting to meet all their needs.

Usually manufacturing organization does not possess sufficient resources to successfully meet the exact needs of every potential customer or market segment and even though if they try to fulfil, requirement handling becomes too complex for them. In such cases, these organizations are forced to focus resources on selected customers and segments.

As a result, they have to decide where to compete and where not to compete based on the fit between their strengths and customer needs. But limiting the number of products, segments or customers is not a solution.A differentiated supply chains in such cases comes handy and transform such threat situation into pool of opportunities.

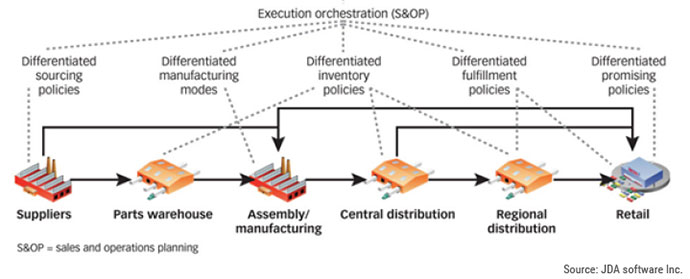

According to a survey done by PwC in 2013, about 44% of emerging-market companies are investing in differentiated supply chain capabilities to stay ahead from competition in the volatile and competitive market.Against the backdrop to remain competitive, supply chain organizations are preparing themselves for by splintering their traditional supply chains into smaller, nimbler ones, which are better prepared to manage higher levels of complexity with customize service levels.These multiple supply chains can be grouped with respect to product, volatility, velocity, where what is made or sourced, when sold and market segments. In essence, a single physical supply chain can work as multiple virtual supply chains governed by differentiated sourcing, manufacturing, Inventory and fulfilment policies. These virtual supply chains will be driven by unique value propositions for group of customers.

It required to perform regular demand and cost to serve analysis. This should be backed up by data driven analysis of demand dynamics and profitability of the customers and its products. After this analysis, service agreements and supply chain policies can be tailored in order to raise the overall profitability. As dynamics of demand changes frequently in today’s landscape, it is required to perform this analysis on a regular interval. The objective for such an analysis is to understand which customers/products are profitable.

Implement differentiated inventory policies to make the decisions regarding what inventories to carry, where, in what form and in what quantities across the entire supply chain. It is required to use analytical tools to evaluate the entire network and determine the stocking policies for each product at each stocking location. This process will determine how much FG inventory to carry at regional DCs, at central DCs and at the factory locations for different product categories.

.jpg?width=282&height=146&name=New%20Project%20(1).jpg)

We worked with one of the leading automotive suppliers which had a complex product portfolio and sales of the different products varied.

However, a small proportion of its products represented a significant volume of sales. So, an efficient supply chain was designed purely to handle this stable segment and a second, more responsive one to deal with less predictable demand. These two supply chains worked in tandem, but didn’t get in each other’s way.

.jpg?width=312&height=267&name=New%20Project%20(2).jpg)

Differentiated supply chains helps manufacturers not only with operational benefits like increase flexibility and responsiveness and enable better demand planning but also helps take a market-back view of things in which the needs of product development, customers, and markets are taken into account all at once.

A disorganized approach of the past used to optimize each step of the chain in isolation. But a differentiated supply chain strategy takes a holistic view, which has potential to unlock new opportunities for organizations to find ways to be more efficient while catering to more consumers.

Adopting a differentiated supply chain strategy is not simply a matter of flicking a switch. Any organization considering such a switch in strategy would have to spend some time strengthening its internal capabilities, institutionalize prudent change management and would need to reconfigure there IT systems.

© 2025 CGN. All rights reserved.